if you are not fully satisfied, we

will refund your investment… Period

Boost My Production

Whatever your material: if you can extrude or roll it, we can notch, pierce, slot, trim, or cut it.

We provide our partners competitive advantages and reduced costs by building machines that enable:

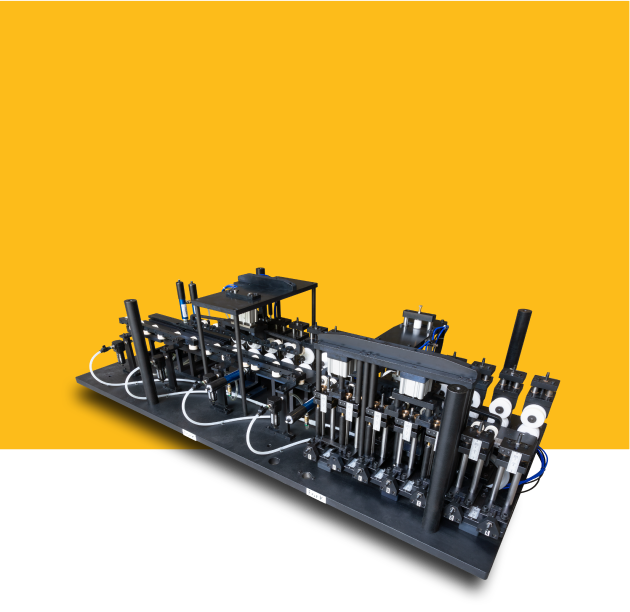

Single Operation Fabrication

Complex profile

one-punch processing

Speed and efficiency of complete fabrication

Reduced tool change downtime

Reduction in scrap

Increased throughput

Boost My Production

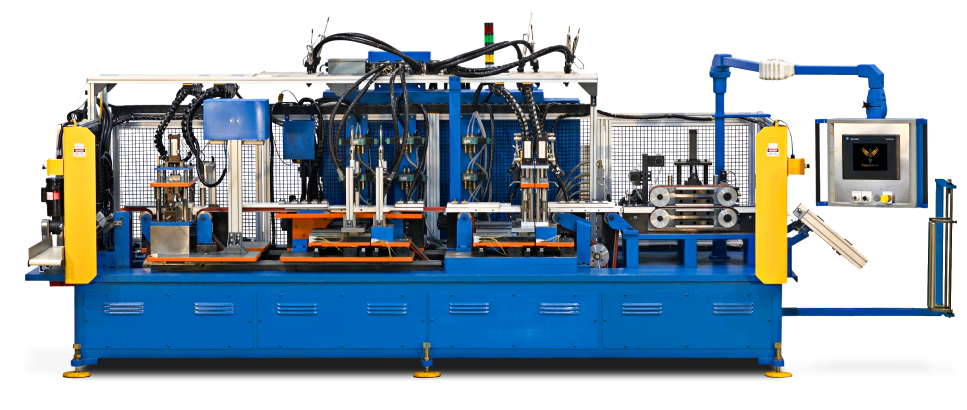

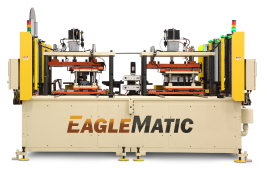

For generations, EagleMatic has been the leading provider of custom in-line cutting and punching systems.

Why? Because we get results for leading companies in the toughest industries.

Here’s just a few:

These industries turn to EagleMatic because our commitment to quality matches their own.

EagleMatic’s custom in-line cutting and punching systems are critical for companies looking to increase throughput, reduce waste, and boost precision. We help our clients by:

· Creating cut-to-length machines that achieve tight tolerances

· Minimizing total production cost

· Developing custom one-punch processing

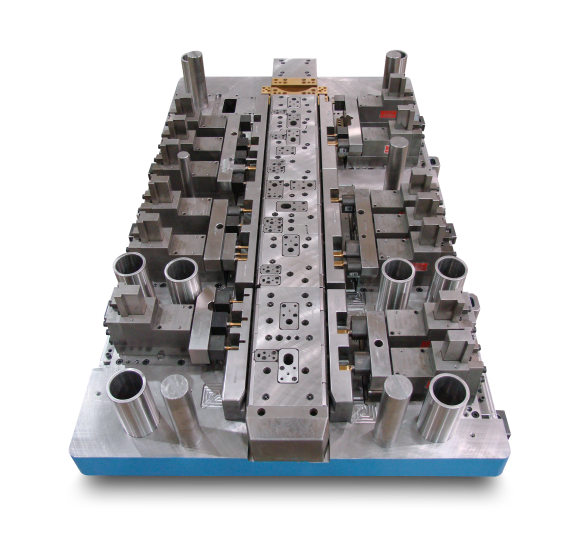

· Designing and building all necessary tooling

· Reducing scrap

Boost My Production

Our systems meet the most rigid specifications for productivity and quality control requirements while being able to handle any kind of extruded profile.

We also design and build all the necessary tooling for your particular needs. Because Eaglematic builds universal systems, we can modify, retool, or retrofit your basic press with totally new tooling.

Nothing excites us more than a new manufacturing challenge. So talk to us about your application and manufacturing requirements.

All we need are engineering prints, material specs, and production quantities to deliver a no-obligation quote.

Boost My Production

EagleMatic is the leader in the design and fabrication of universal systems for in-line punching of extruded plastic profiles and roll-formed sections.

We’ve earned this reputation because for more than sixty years, EagleMatic has pioneered in-line cutting and punching systems for our partners. By synchronizing the travel speed of the punch die with the line speed of the material we are able to punch on the fly with precision and speed that exceed industry standards.

Don’t just take our word for it.

Read these case studies to see how EagleMatic is transforming businesses across the country.

Ready to transform your business?

NAVIGATION

SERVICES