Latest technology

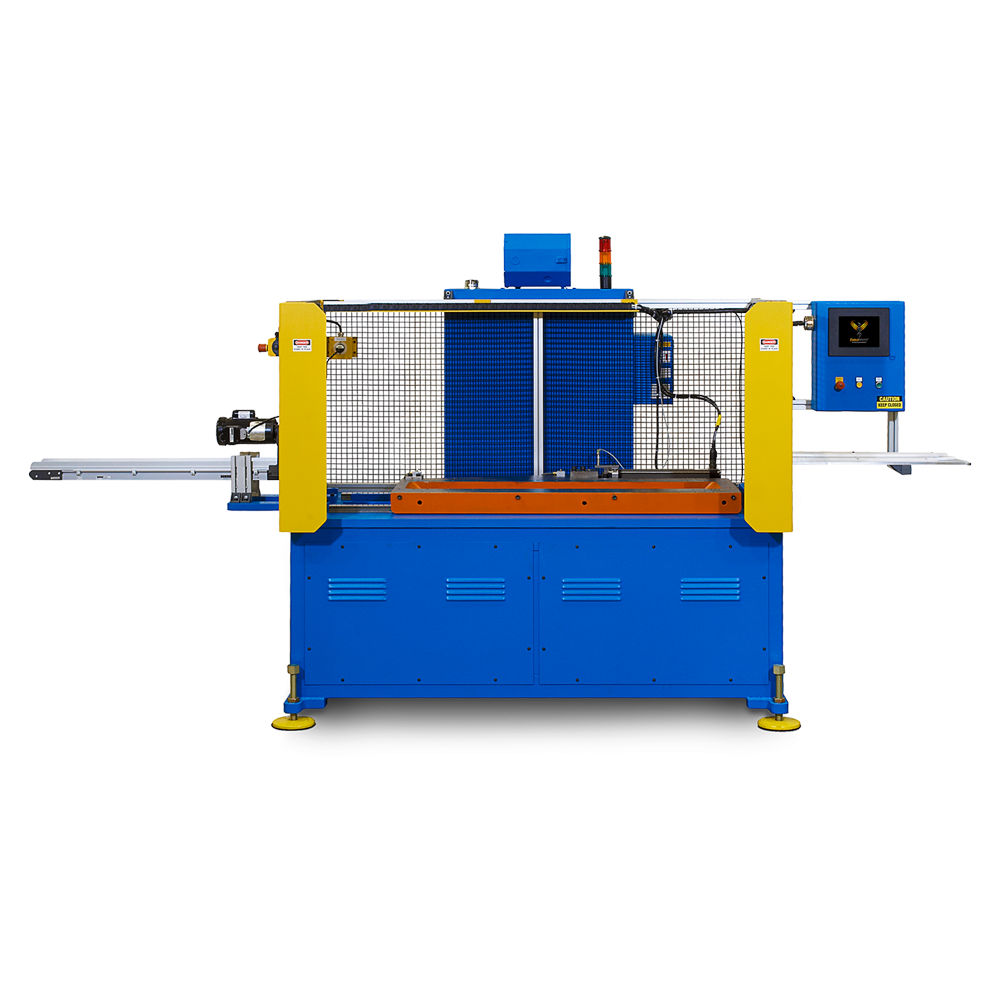

Using the latest technology in our in-line punching and cutting machinery offers numerous benefits for our plastic extrusion and roll-forming customers. Servo motors provide precise and accurate control over the movement and positioning of the cutting tools, ensuring consistent and high-quality results.

Apart from servo motors, our machinery incorporates advanced sensors, programmable logic controllers (PLCs), and human-machine interfaces (HMIs) to enhance productivity and ease of use. These technologies enable real-time monitoring, automatic adjustments, and seamless integration with other manufacturing processes. By embracing cutting-edge technologies, we ensure that our clients receive the most efficient and reliable punching and cutting solutions for their specific needs.

Superior Surface coatings

EagleMatic machines also feature superior surface coatings that offer exceptional durability and performance. The surface coatings applied to our machinery provides protection against corrosion, abrasion, and wear, extending the lifespan of the equipment and reducing maintenance requirements. These coatings are engineered to withstand harsh operating conditions, ensuring that our machines can deliver consistent and reliable performance even in challenging environments.

The advanced surface coatings also contribute to improved efficiency by reducing friction and eliminating the need for lubrication in certain parts. With our superior surface coatings, our clients can trust that our machines will not only deliver outstanding results but also have long-lasting functionality, making them a valuable investment for their manufacturing operations.

Data Collection

Our machines are equipped with advanced data analytics capabilities. The integration of data analytics enables our clients to gain valuable insights into their manufacturing processes and make informed decisions. By collecting and analyzing real-time data, our machines can provide key performance indicators, production trends, and predictive maintenance alerts.

This data-driven approach empowers our clients to optimize their operations, improve efficiency, and reduce downtime. With the ability to monitor and analyze data, our clients can identify areas for improvement, streamline workflows, and enhance overall productivity. Our data analytics capabilities ensure that our clients have access to the latest tools and insights to maximize the performance and profitability of their manufacturing processes.

High-speed Materials

High-speed steels are known for their exceptional hardness, toughness, and heat resistance, making them ideal for applications that involve high-speed cutting and punching. They can withstand the high temperatures generated during the process while maintaining their cutting edge, resulting in improved productivity and longer tool life.

Carbides offer excellent wear resistance and hardness, making them suitable for abrasive materials and high-temperature applications. Their ability to retain their shape and cutting edge for prolonged periods reduces the need for frequent tool changes, enhancing efficiency.

Ceramics, on the other hand, provide superior hardness, wear resistance, and thermal stability. They can withstand extreme heat and offer exceptional cutting performance, making them ideal for challenging materials. Incorporating these advanced materials in our machinery allows us to deliver precise, high-quality punching and cutting solutions to meet the diverse needs of our clients.

Greaseless Components

We incorporate greaseless components whenever possible. Greaseless components eliminate the need for regular lubrication and maintenance, saving valuable time and resources. By eliminating grease, the risk of contamination is significantly reduced, ensuring cleaner and safer working conditions. Additionally, greaseless components offer improved reliability and durability due to their self-lubricating properties.

This results in decreased downtime and increased productivity, as the machinery can operate smoothly and efficiently for extended periods. Moreover, the absence of grease reduces the environmental impact, making our operations more sustainable. By utilizing greaseless components in our machinery, we can provide our clients with cutting-edge solutions that deliver optimal performance, minimal maintenance, and enhanced productivity.

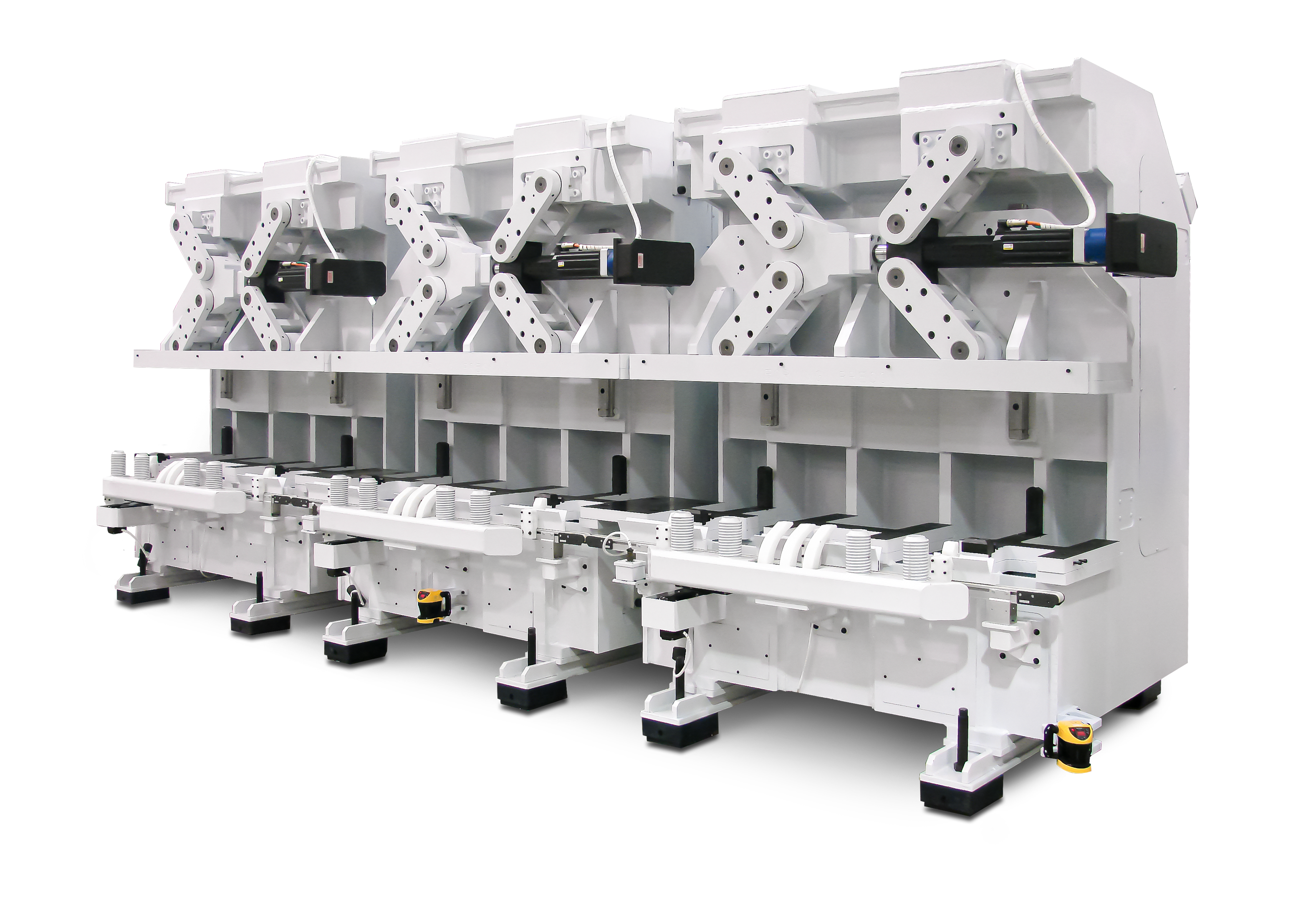

Heavy Duty tooling

Using heavy-duty tooling in our dies for in-line punching and cutting machinery offers numerous benefits to your operations. Heavy-duty tooling is specifically designed to withstand high-stress applications and heavy loads, ensuring superior performance and durability. By using robust and sturdy tooling, we can achieve precise and consistent results even when working with challenging materials or complex designs.

This enhances the overall efficiency and productivity of our machinery, as it can handle demanding tasks with ease. Additionally, heavy-duty tooling minimizes the risk of premature wear, reducing the frequency of tool replacements and resulting in cost savings for our clients. With our heavy-duty tooling capabilities, we can provide reliable and long-lasting solutions that meet the toughest requirements of our customers, delivering exceptional results every time.

High Quality components

Using high-quality components from renowned brands such as Alpha Wittenstein, Rockwell Automation, Mitsubishi, and Allen Bradley brings numerous advantages to our in-line punching and cutting machinery. These brands are known for their commitment to excellence, reliability, and innovation in the field of industrial automation. By incorporating components from these trusted brands, we ensure that our machinery operates at its peak performance, delivering accurate and consistent results.

The use of high-quality components enhances the overall reliability and durability of our machines, reducing the risk of breakdowns and minimizing downtime. Moreover, these components often come with advanced features and technologies that improve efficiency, precision, and safety. By partnering with top brands, we can offer cutting-edge solutions that meet the highest standards of quality and performance, providing our clients with the best possible results.

Robotic Integration

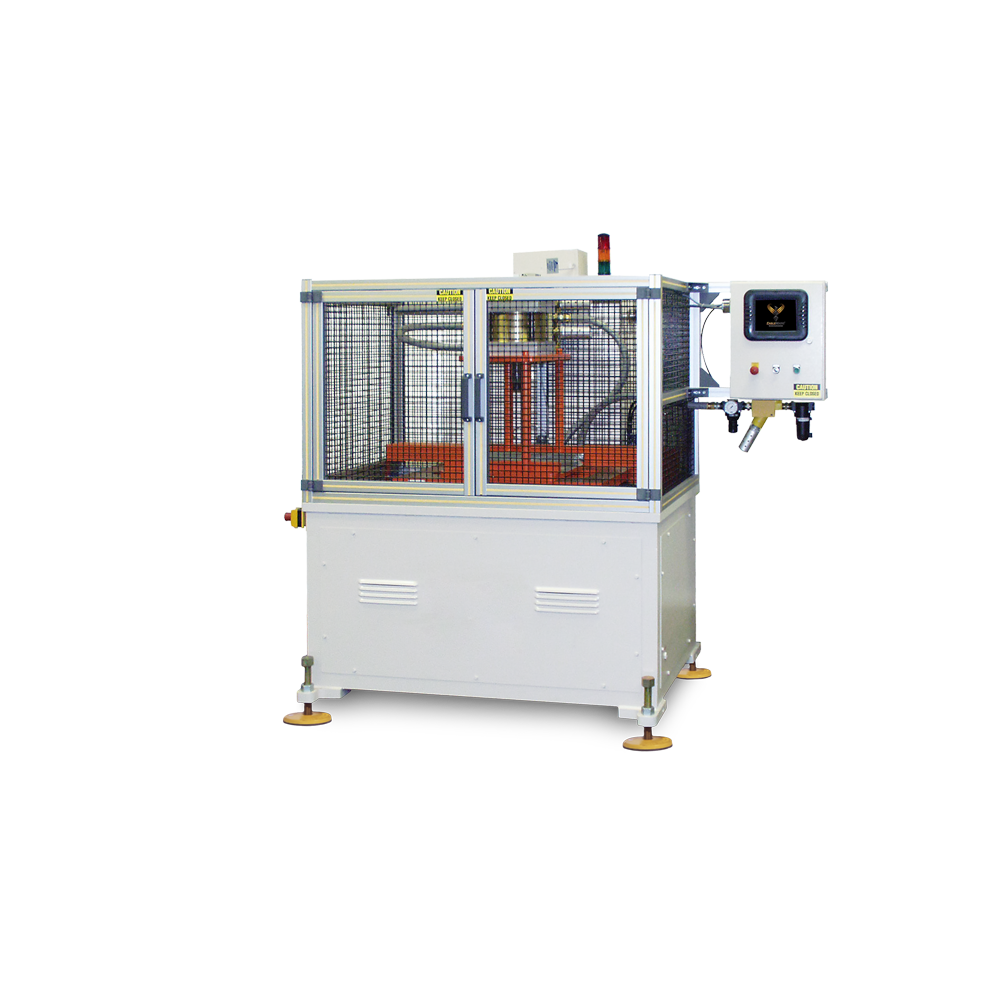

By combining the precision and efficiency of robotics with the punching and cutting capabilities of our machinery, we can achieve unparalleled levels of productivity and accuracy. Robotics enable seamless automation, eliminating the need for manual intervention in repetitive tasks. This not only reduces labor costs but also minimizes the risk of human error, ensuring consistent and high-quality output.

Additionally, robots can perform intricate and complex operations with speed and precision, enhancing the overall efficiency of our machinery. With advanced sensors and programming capabilities, robots can adapt to varying material properties and cutting specifications, resulting in optimal performance and reduced material waste. By integrating robotics into our machinery, we empower our clients with cutting-edge solutions that enhance productivity, accuracy, and profitability.

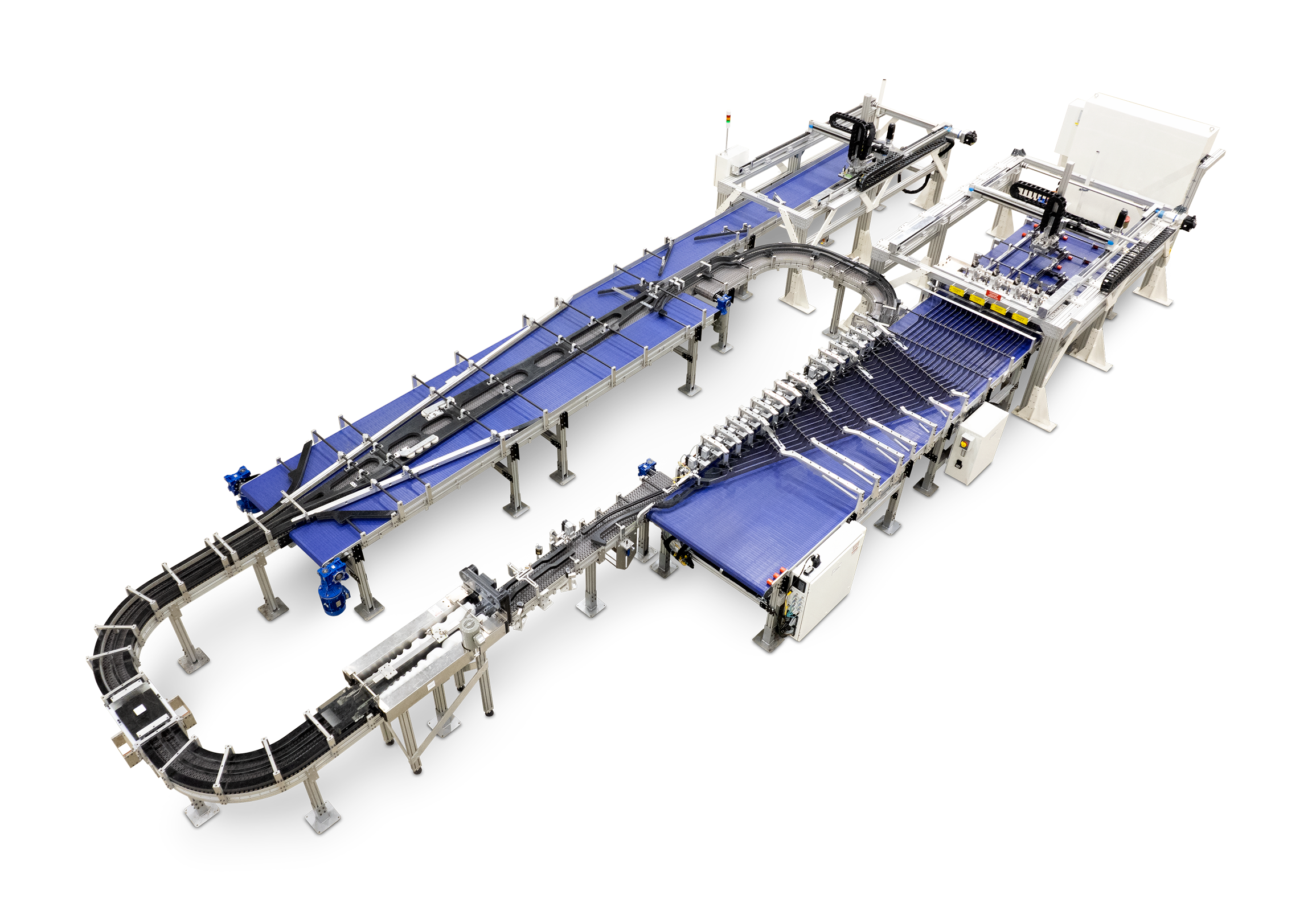

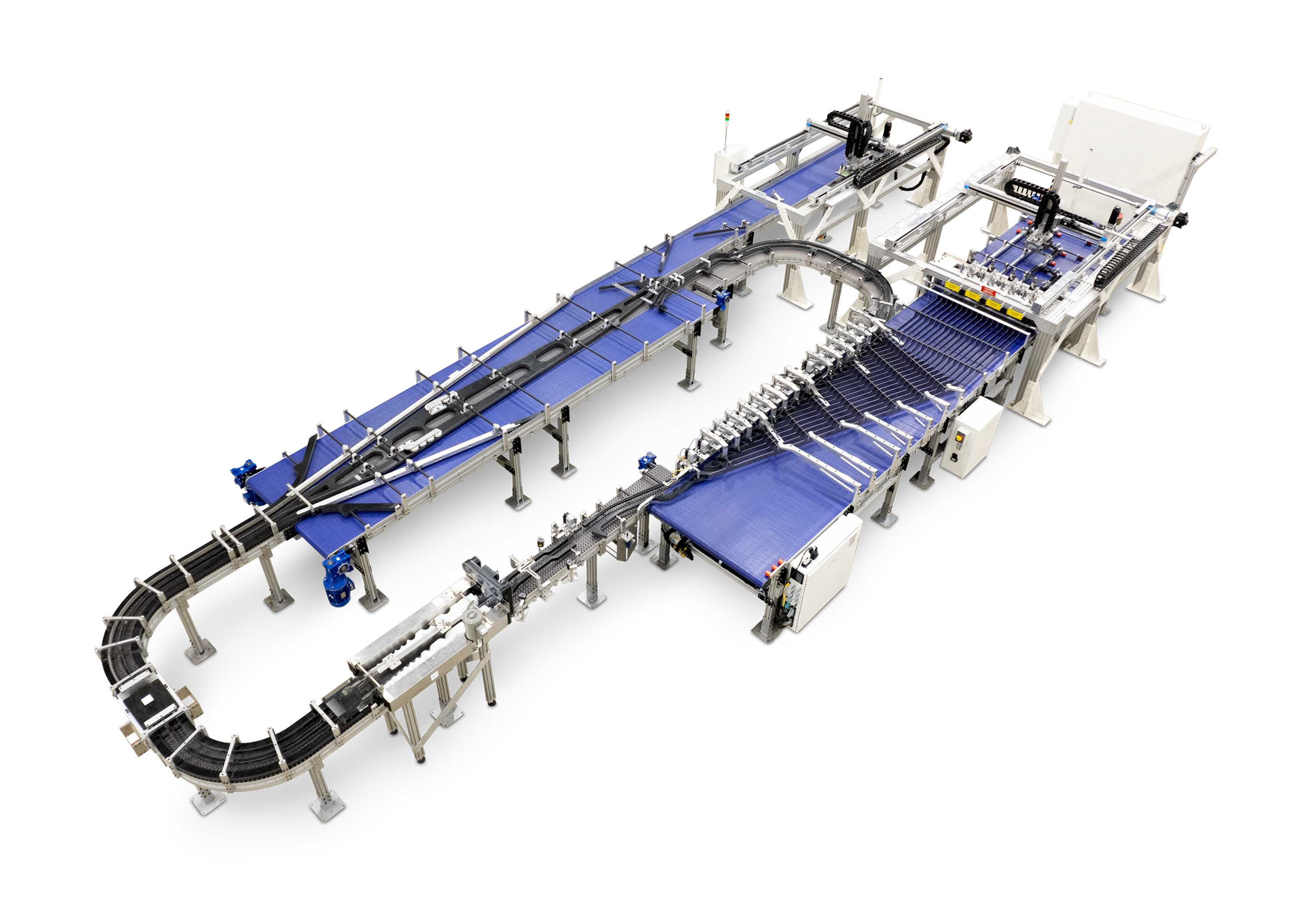

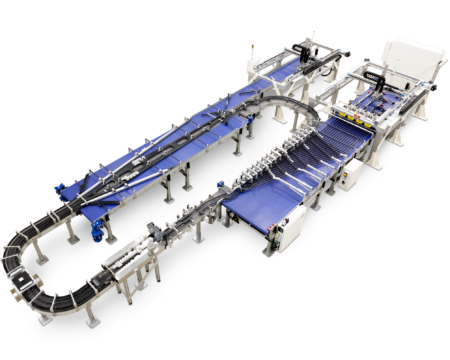

Upstream & Downstream

Integrating upstream and downstream processes with our in-line punching and cutting machinery offers a streamlined and efficient production workflow. Upstream processes such as laser printing, taping, and other preparatory tasks can be seamlessly integrated into the initial stages of the production line. This ensures that materials are properly labeled and prepared before they enter the cutting and punching stages, reducing errors and improving traceability.

Downstream processes, such as weighing, packaging, and labeling, can be seamlessly incorporated after the cutting and punching operations. This integration allows for a smooth transition from manufacturing to packaging, ensuring that the finished products are accurately weighed, properly packaged, and correctly labeled for shipment or distribution. By integrating both upstream and downstream processes, we can optimize the overall efficiency of our machinery, minimize production bottlenecks, and deliver a streamlined and comprehensive solution for our clients.