Industrial Robotics

We integrate robotics from leading companies such as Kuka, Mitsubishi, FANUC, and Universal Robots to ensure precision in our custom automation systems. These industrial robots are engineered to automate repetitive, labor-intensive, and potentially hazardous tasks, thereby enhancing productivity, improving worker safety, and reducing manufacturing costs. The integration of custom automated machinery is pivotal in driving operational efficiency and achieving manufacturing excellence.

These robots operate with exceptional precision, speed, and consistency, leading to improved product quality and reduced production errors. Furthermore, industrial robotics contribute to environmental sustainability by streamlining processes and minimizing waste, aligning with the principles of lean manufacturing. Whether its a Gantry robot, a SCARA pick and place robot, or a robotic welding cell, we have you covered.

Big Data Collection

We systematically gather, measure, and analyze data from various machine components, enabling us to extract valuable insights, make informed decisions, and enhance overall performance. Our role in deploying custom automation equipment and engineering automation solutions that leverage data collection is instrumental in optimizing processes, improving operational efficiency, and fostering innovation.

Our capabilities extend to:

- Facilitating informed decision-making by providing data-driven insights.

- Streamlining processes through optimization based on collected data.

- Enhancing quality control by tapping into the power of accurate and reliable data.

- Creating personalized customer experiences by understanding customer needs through data analysis.

- Empowering predictive analytics by using gathered data to anticipate future trends and behaviors.

Artificial Intelligence

As the world evolves, we adapt. Integrating AI into your equipment can offer invaluable insights into your processes. Data acquisition through AI enables us to optimize your operations and drive innovation.

AI can analyze sensor data to predict breakdowns and accidents. Synthetic intelligence systems assist production facilities in anticipating future failures in operational machinery, facilitating proactive maintenance and repairs. Embracing AI-driven solutions is crucial for staying ahead in the era of industrial automation and automated manufacturing.

- Reduce unplanned downtime

- Enhance Efficiency

- Boost your product quality

- Reinforce the safety of your workers

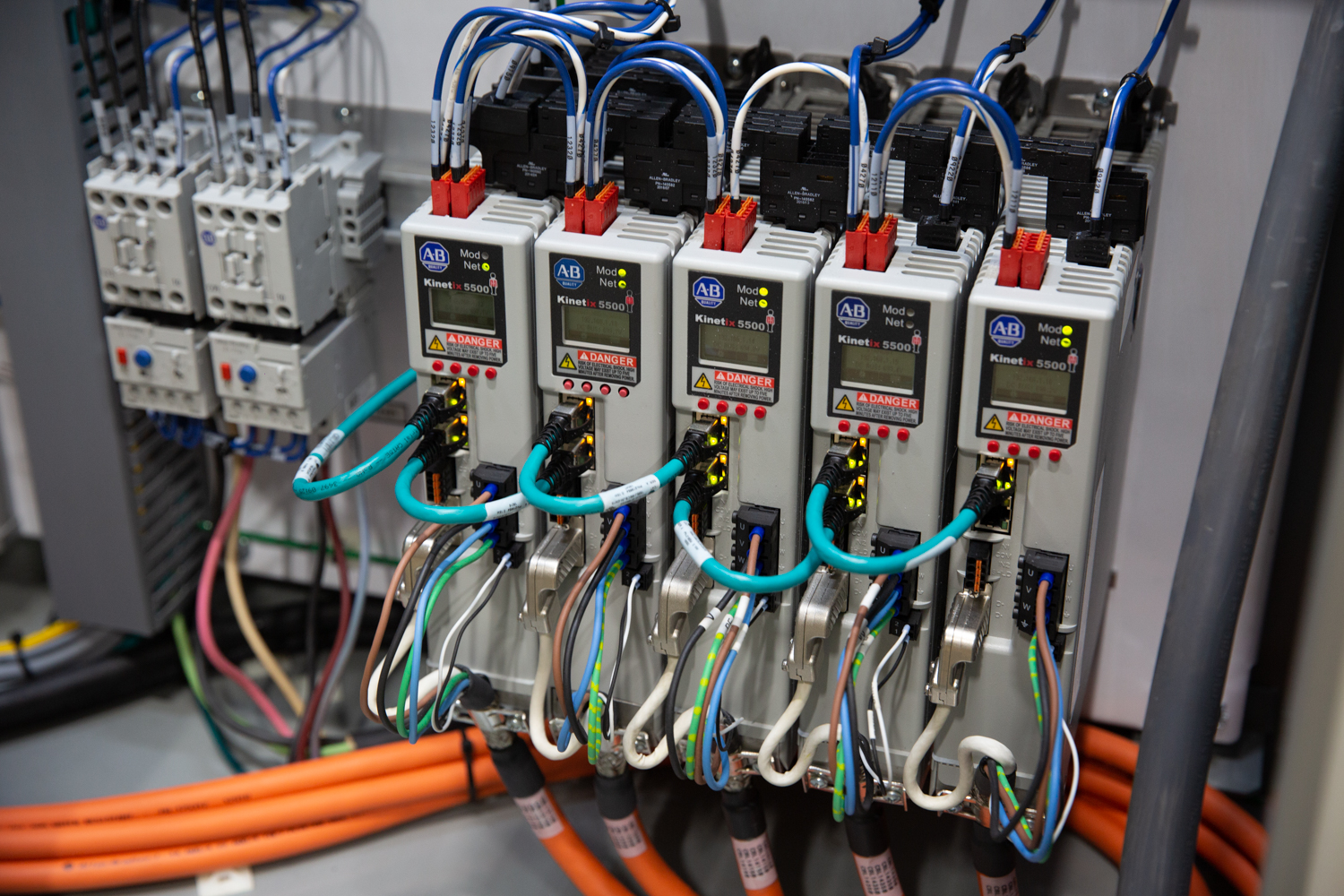

Machine Control

Eagle Manufacturing specializes in providing custom automation solutions, offering both PLC and PC Machine Control. Our custom controls for our automation machinery are designed to operate in extreme conditions, providing real-time control and flexibility in your application. Whether you require ruggedness, reliability, or advanced functionality, Eagle has you covered with various Machine Control solutions in our automation systems. We understand the benefits of automation in manufacturing and can tailor our solutions to meet your specific requirements.

Both PLC and PC Machine Control systems have their merits and can be suitable for different applications. PLCs are typically preferred for their ruggedness, reliability, and real-time control capabilities, while PC Machine Control systems offer flexibility, advanced functionality, and easier integration with other software systems. The choice between the two depends on the specific requirements of the application and your organization’s priorities. Our custom automation equipment design ensures that you get the most suitable system for your needs.

Vision Systems

Our company possesses the expertise to implement vision systems integrations that utilize cameras, sensors, and advanced software to capture, scrutinize, and interpret images. This technology is instrumental in guiding, inspecting, and identifying objects within automation manufacturing and production landscapes. It significantly boosts the effectiveness, precision, and dependability of our automated procedures. The potential applications of our vision systems are multifaceted, encompassing data acquisition, engineering automation, and industrial automation.

- Quality inspection to ensure the highest product standards

- Robot guidance to streamline automated processes

- Optical character recognition (OCR) for seamless data extraction

- Barcode and 2D code reading for efficient inventory management

- Automated measurement for accurate product specifications

Servo Motor Control

Investing in our Servo-Controlled Systems is a strategic move that will bring immediate and long-term benefits to your business. Servo motors offer numerous benefits, including high output power, unparalleled accuracy and resolution, and energy efficiency. These advantages make servo systems an essential component in modern automation and manufacturing processes. There are many reasons why you should consider using servo motor control in your custom automated equipment, here are a few of them:

- Precision and accuracy

- High torque at low speeds

- Fast response time

- Closed-loop control

- Energy efficiency

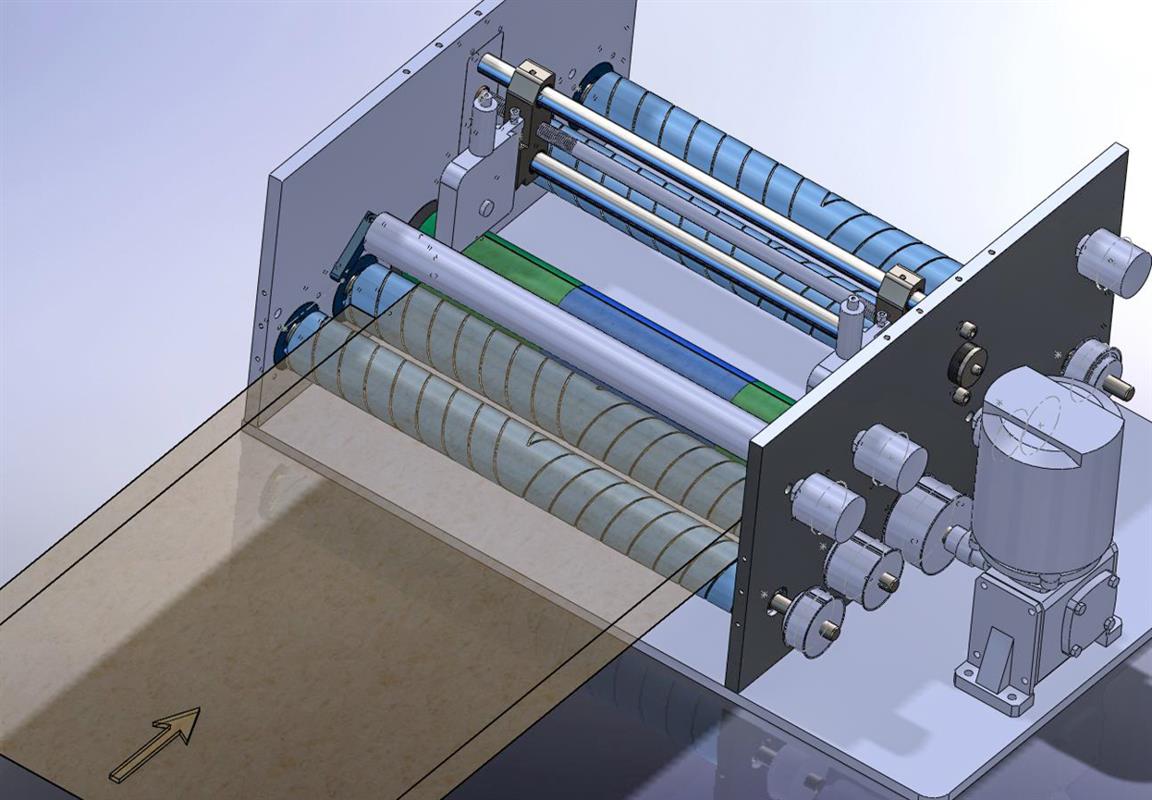

Material Joining Systems

Our Material joining systems can include technologies like welding, soldering, adhesive bonding, and mechanical fastening. These processes can be automated using tools like robotic arms, servo and stepper motors, and advanced control software. Automation in material joining systems ensures consistent and accurate results, leading to improved product quality and faster production times. Our custom fabrication and manufacturing systems are designed to meet the specific needs of your business.

The use of automation in material joining systems also enables real-time monitoring and adjustment of process parameters, such as temperature, pressure, and speed. This closed-loop control ensures optimum performance and minimizes defects or inconsistencies in the final products. Thus, material joining systems in automation play a crucial role in enhancing production efficiency, reducing costs, and maintaining competitiveness in the manufacturing industry. Our custom automated machinery is equipped to handle these complex tasks with precision and efficiency.

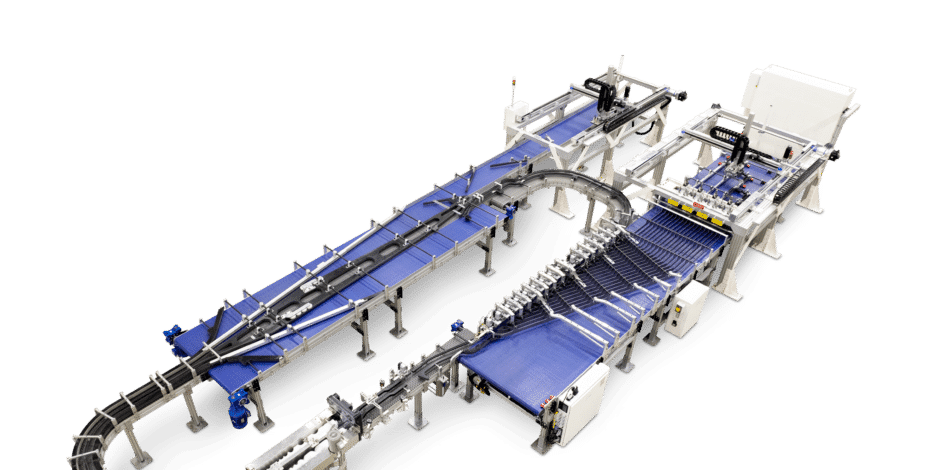

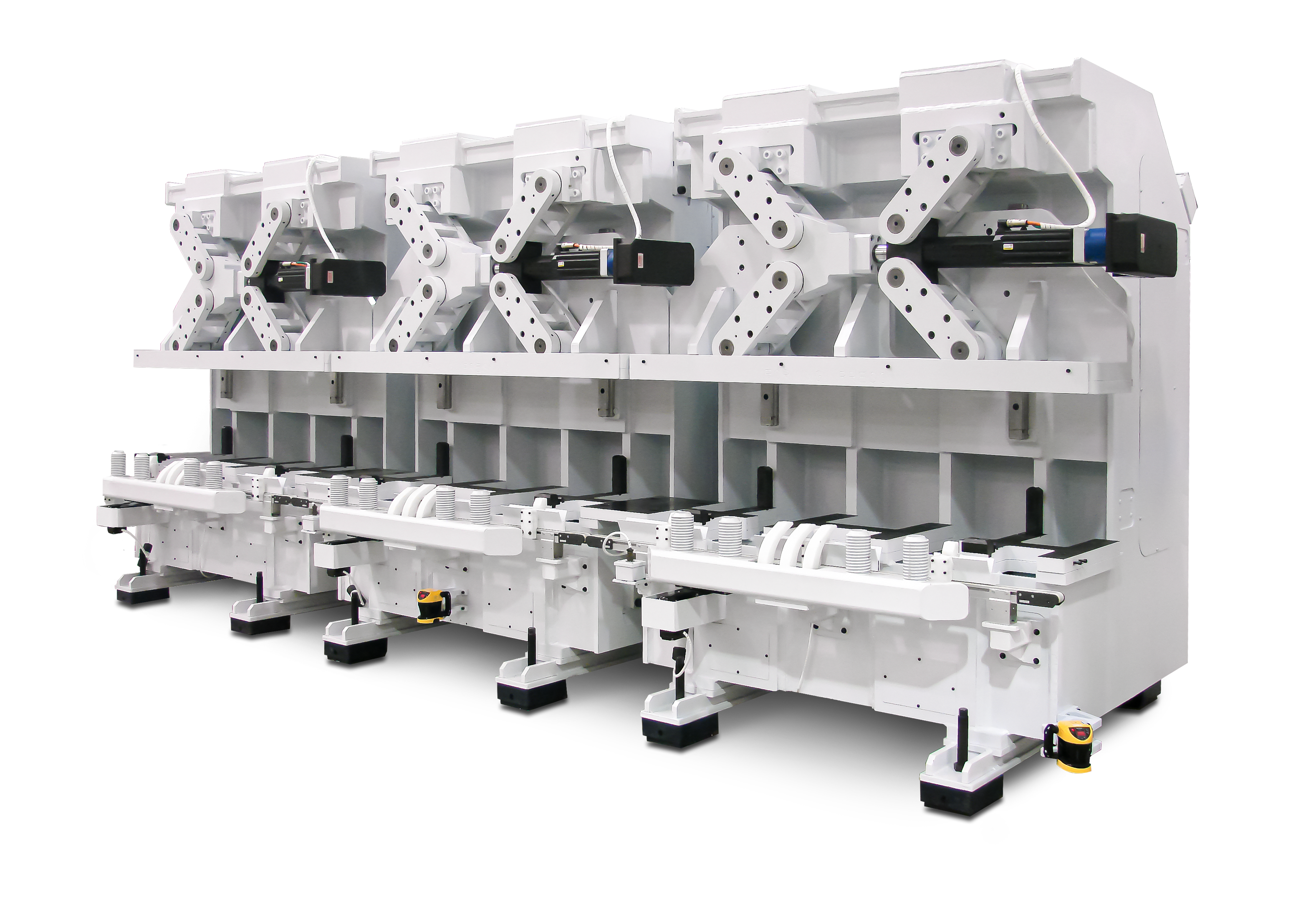

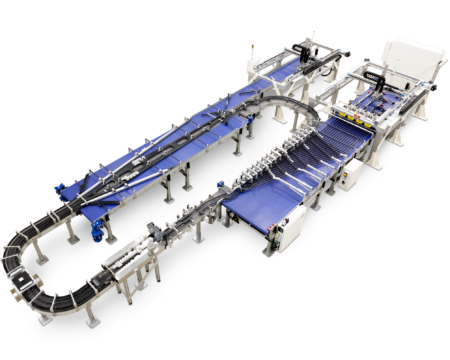

Assembly Machines

A high-speed, multistation automated assembly system can produce tens of thousands of products per day. Our custom assembly systems are designed to maximize productivity and efficiency, ensuring that your manufacturing processes run smoothly and seamlessly.

Our assembly machines can range from simple, single-purpose devices to complex, multi-functional systems capable of handling a wide variety of assembly tasks. They typically incorporate several technologies, such as robotics, vision systems, sensors, and programmable logic controllers (PLCs), to ensure precise and accurate assembly operations. They can perform tasks like part picking and placement, screwing or fastening, gluing, soldering, and other joining processes. Our assembly systems are fully automated, offering the benefits of fully automated manufacturing and customization.

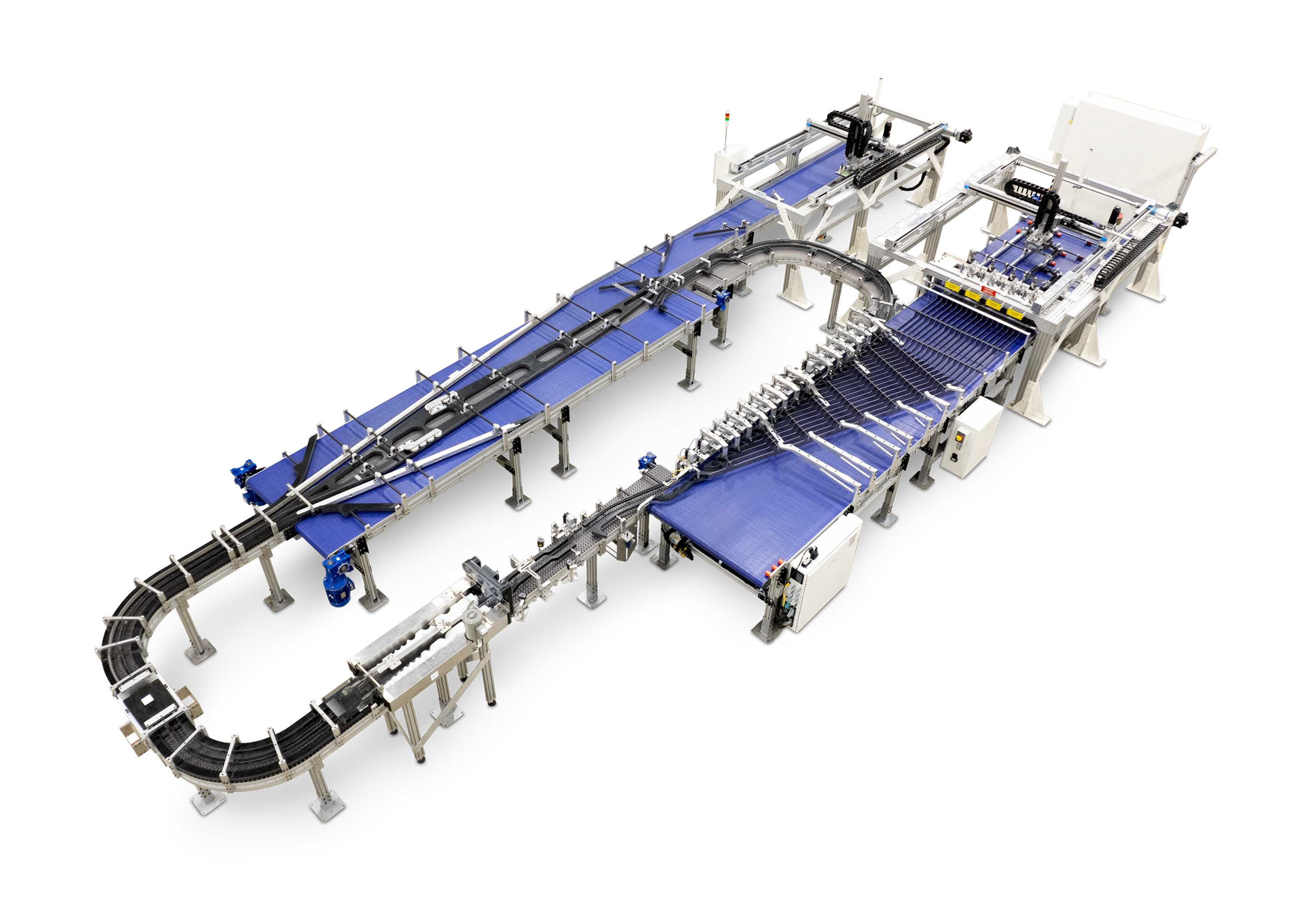

Packaging Systems

Our automated packaging systems encompass various stages of the packaging process, including product handling, filling, sealing, labeling, and palletizing. Automation allows businesses to automate repetitive and time-consuming tasks, freeing up employees to focus on more critical tasks, improving overall efficiency. Our fabrication services extend to automated packaging systems, ensuring that your products are packaged efficiently and accurately. These stages can be automated using a combination of technologies:

- Robotic arms

- Conveyor systems

- Filling and sealing machines

- Labeling machines

- Vision systems

- Palletizing systems

- Control software